How the Kanban System of Inventory Management Works

The goal of a Kanban inventory system is to continually maintain the minimum amount of stock. The beauty of the way the supermarket managed its inventory was that it only stocked items it expected to sell them in a given time. For instance, the supermarket didn’t order more cases of sardines when there were already plenty in stock. Instead, goods sold were monitored at the supermarket and would be re-stocked accordingly. When Toyota rolled out TPS in its factory, the company also introduced six rules.

Toyota’s Six Rules for Effective Kanban Systems

- Customer (downstream) processes withdraw items in the precise amounts specified by the Kanban.

- Supplier (upstream) produces items in the precise amounts and sequences specified by the Kanban.

- No items are made or moved without a Kanban.

- A Kanban should accompany each item, every time.

- Defects and incorrect amounts are never sent to the next downstream process.

- The number of Kanbans is reduced carefully to lower inventories and to reveal problems.

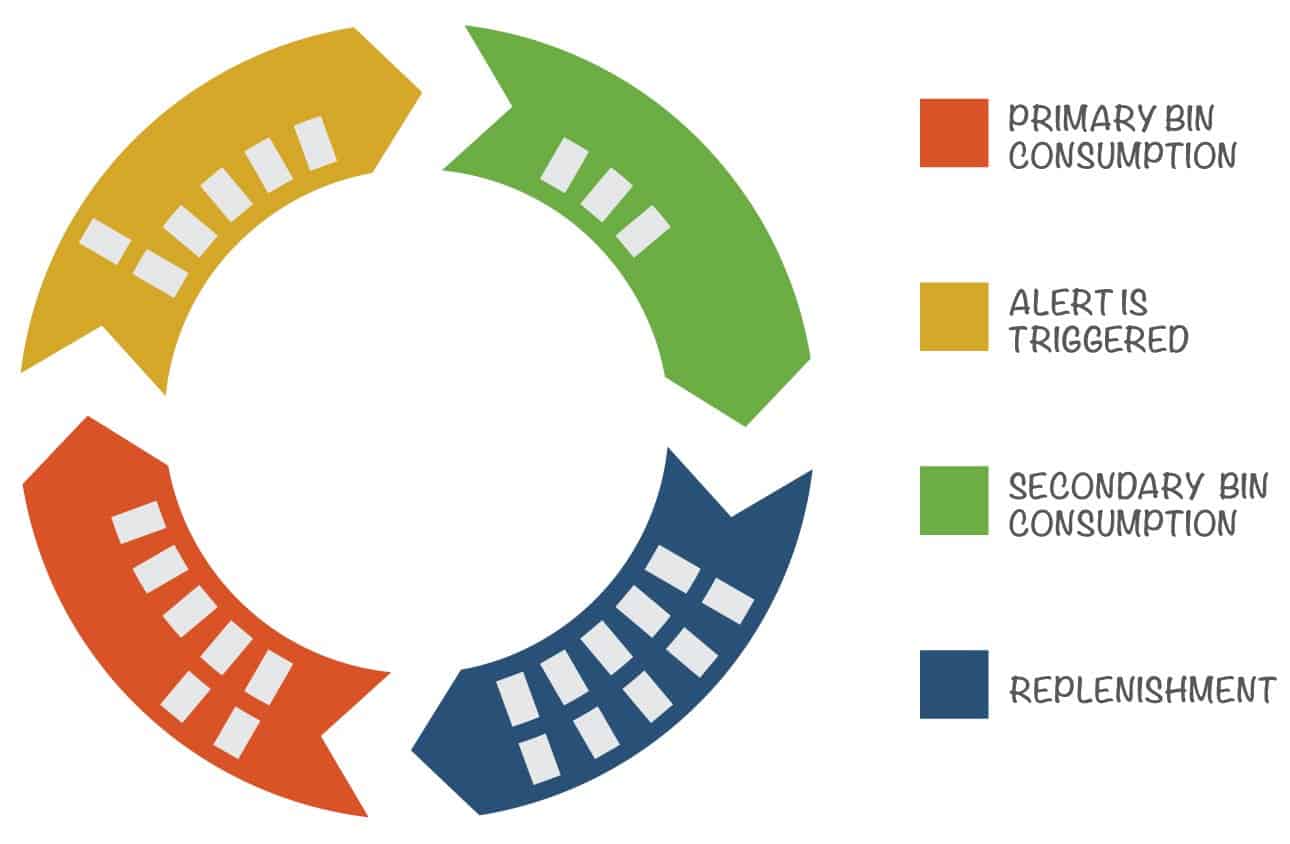

Similarly, the Kanban system aligns inventory needs with what is actually being used. This is often referred to as ‘pulling.’ When the stock of a specific item is depleted, the supplier is signaled to deliver a new shipment, and the signal to place another order is tracked through the replenishment cycle. In this way, it’s simple to track how often restock is needed. In a Kanban inventory system, a company can use Kanban cards or bins to signal when stock needs to be refilled.

In the Kanban bin system, companies rely on visual cues to start the restocking process. Workers have two containers of inventory and work through the supplies in one bin before moving on to the other. When the first bin is empty, it sends a trigger to reorder inventory. Ideally, by the time a worker reaches the end of a second bin, the stock will be refilled. Before determining the amount of stock in any one bin, it’s important to know how long it will take to get new inventory from the supplier. Stock that can’t be replenished by the time the second bin is empty will cause a lag in production.

Benefits and Obstacles of a Kanban Inventory System

Kanban’s logical approach to monitoring inventory levels and meeting customer demand makes sound business sense. However, there are certain things that need to be accounted for before a solid system can be put in place. Understanding the many benefits and potential drawbacks of using a Kanban inventory system will help ensure that your team is successful in implementing Kanban.

7 Benefits of a Kanban Inventory System

Here are some of the advantages of using a Kanban inventory and management system:

- Reduce Inventory Levels and Costs: When you don’t have a lot of inventory to store, there’s more space available to work. Additionally, only stocking the amount of inventory needed saves money, because you’re not using the business income to purchase items that aren’t going to be used.

- Customer Demand Determines Need: You’ll be able to easily identify which of your products are selling well since you’re only restocking as inventory is depleted. If the parts needed for one item are rarely replenished, it is likely not a high-demand product.

- No Storage in the Production Area: In Kanban, parts are only delivered to the production line when needed. This space savings provides ample room on the production line for workers to assemble the product.

- Provides Managers Progress Reports: Kanban software can provide analytics that show how much product is being produced and how long it takes. Powerful Kanban inventory software can run a bevy of reports that help managers plan, organize, and improve workflow.

- Reduces Obsolete Inventory: If a company over-produces inventory, it often sits in a stockroom for long periods of time, and companies have to decide what to do with the excess (sell, give away, or discard). Additionally, when stock isn’t touched immediately, it can be difficult to determine if there are damaged units. You don’t want to wait until the defect is discovered on the production floor, possibly six months down the line, when there’s not much you can do about it.

- Prevents Overproduction: When you’re only pulling items needed (determined by customer demand), it’s unlikely you’ll end up sitting on an excess of products that aren’t selling.

- Lean Inventory: As noted previously in this article, Kanban works well with Lean manufacturing. When you use Kanban in conjunction with Lean manufacturing, you don’t have excessive inventory which helps eliminate obsolete or defective stock items.

Obstacles to Overcome When Implementing a Kanban Inventory System

The benefits of a Kanban system are plentiful and will save money and increase efficiencies. However, before setting up a Kanban inventory system there are a few things to keep in mind. You’ll need to closely monitor the amount of inventory currently being used so you’ll know how much should be ordered when restocking. This process will take time, so expect an initial fluctuation in bin levels while you figure out your inventory patterns and therefore, needs. Be aware that you may experience a slow in production while you figure out Kanban levels.

To help determine how many items should go into each bin, you’ll need to know how long it will take for a supplier to deliver the items. Then, build that time into determining how many items to put in each bin. For example, if you put five items in each bin and it takes 10 days to go through each bin, the supplier needs to deliver the new stock within six to eight days to avoid production delays.

Formula to Help Develop a Two-Bin Kanban Inventory System

For a Kanban inventory and scheduling system to be effective, you need a firm understanding of the existing inventory flow and restocking process. While it will probably take a few attempts to get the system working seamlessly, there are Kanban formulas that can help with the initial setup. Here’s a Kanban equation that Oracle developed:

Number of Kanban = (C-1)*S=D*A*(L+SSD)

- C: Number of Kanban cards

- S: Size of the Kanban

- A: Allocation present

- L: Time needed to replenish the inventory

- D: Average daily demand of a particular product

- SSD: Safety stock days

Kanban Inventory Control Software

Thanks to barcodes, RFID tags, and software, keeping track of inventory levels and patterns has been made much easier in recent years. There are plenty of Kanban inventory software solutions available that help automate the process. While the physical two-bin system may be in effect on the production line, Kanban inventory software uses cards that are connected to the barcodes or RFID tags in the bins and an electronic database to track and restock the inventory.

A robust automated Kanban inventory system will be able to manage the complete supply chain. The system can signal and place a restocking order when the first bin is depleted, and can also track lead and replenishment times to ensure the right amount of stock is always available on the production line. Additionally, managers can use the inventory system to run reports on productivity and see which products are selling. Since these pull-based inventory systems span a myriad of business departments, it should be managed by a cross-functional team and enable stakeholders to view and act on real-time data.

5 Companies Using Kanban Inventory System to Increase Efficiencies and Save Money

Although Kanban originated on the factory floor, it can be used in any industry to better manage the supply of products. Now that you know how a Kanban inventory and management system works and how using one can save money while increase productivity, let’s explore how diverse industries are using it today.

- Managing Medical Supply Carts

At the Seattle Children’s Hospital items such as surgical dressings, specialized tubing, catheters, and clamps were in short supply. Since these items are imperative for care, nurses began stockpiling goods in random locations around the hospital to ensure they had the necessary items to treat patients. This non-standardized inventory stashing caused delays, and the amount of time clinicians spent restocking supply severely cut into what they were actually employed to do: help and treat patients.

The hospital implemented a Kanban two-bin system from BlueBin to remedy the situation. After analyzing the data and workflow for a year, the company determined the optimal levels that should be stocked in supply bins. The stockroom was re-invigorated with a Kanban two-bin system. When one bin is depleted, it is sent to the central supply office where barcodes on the bin are scanned and a new order is placed. Hospital personnel can view the Kanban inventory system dashboard at any time to see every piece of the supply chain. As a result of shifting to Kanban, the storage room shrunk in size, the hospital saved money by not having to discard expired goods, and medical staff has more time to do what they’re there for - care for people. - Electronics Company to Satisfy Online Orders

Milwaukee Electronics, a design and manufacturing company producing parts for medical, industrial, and consumer electronics, as well as aerospace clients, started Screaming Circuits in the early 2000s. Screaming Circuits is an Internet-based QTA turn-key assembly service that develops prototypes and some small volume production. Customers use the company’s website exclusively to generate quotes and place orders. To ensure fast order delivery, Screaming Circuits utilizes a Kanban system for contract customers. The company stocks two week’s worth of inventory and created custom programs with suppliers to ensure that replenishment lead time is two weeks, so they are never in need of parts. As a result, when those customers place a delivery in the afternoon, they can receive the product the next morning. - Sensor Manufacturing Company Simplifies Management of Supplier Network

Dynisco, a leader in plastics extrusion processing and manufacturer of a mercury-free pressure sensor, needed to reduce the cost of carrying excess inventory and enhance efficiency and productivity from existing resources. To tackle these issues, the company implemented design for manufacturing and assembly best practices. Dynisco was able to simplify new product designs, standardize costs, and improve supplier management.

Unfortunately, there were still issues with lead times and quality. The company sought to alleviate these issues with a manual Kanban system. Indeed, the Kanban inventory system helped with the flow of materials and improved client response times. Dynisco still had too much inventory on hand, however, so they turned to SyncKanban to automate the system. The new Kanban inventory system provided accurate inventory and supplier data in less time than it took for them to accomplish it manually. The SyncKanban pull-based inventory replenishment system easily integrated with existing ERP, CRM, and financial products. By making the switch to an automated Kanban inventory system, the company reduced its active inventory by 40% across all facilities. - Restocking Automotive Supplies for a Body Shop

Suburban Collision Center runs three body shops and was looking for a way to improve profits. Like many body shops, they didn’t do a month-end inventory, so they weren’t always certain of what (and how much) was in stock. They needed to organize their inventory and develop a consistent method that could work at each location. The company turned to the Sherwin-Williams Lean Stock inventory story which uses Kanban. With this system, supplies are placed in carts that all the technicians use. When one bin is empty, the technician scans the barcode and new inventory is automatically ordered. The new system has improved productivity, streamlined the organization’s stock supply, increased ROI, and helped the technicians produce a quality product. - Orthopedics Company Consolidates Inventory

In the medical field, suppliers are seeing shrinking margins due to the steady decline of reimbursement. In the orthopedic product industry, companies produce a lower volume of product so they may not immediately see the benefits of a Kanban inventory system. However, dj Orthopedics, a company that creates non-operative orthopedic rehabilitation, regeneration, and repair products, tried Kanban. At one of the company’s plants, they installed a five-sided Kanban device that holds Kanban cards for many of the products stored in inventory. When the items need to be replenished, a card signals suppliers and the crew that manages the storeroom. This system helps reduce the size of the warehouse and cut production time. By deploying a Kanban inventory system along with other Lean manufacturing practices, the company was able to improve its on-time delivery process and continues to increase profits despite the changes in the healthcare field.

Try Smartsheet Card View for Better Visibility into Kanban Inventory Management

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.